Alloy & Temper Specifications

Alcoa & Keymark

Keymark is proud to introduce new low carbon billet from Alcoa…see article here

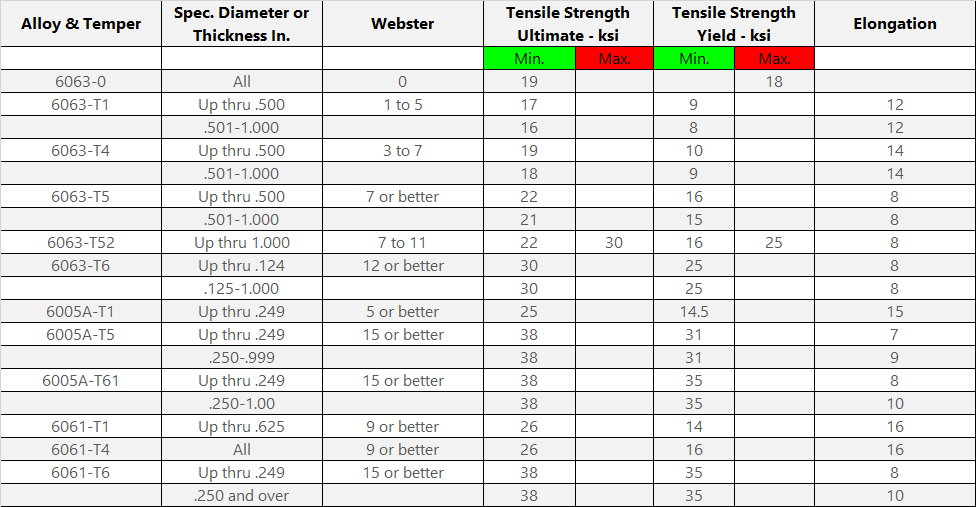

Mechanical Property Limits

6063 Alloy Specification

6005A Alloy Specification

6061 Alloy Specification

Footnotes:

- SI – Silicon

- FE – Iron

- CU – Copper

- MN – Manganese

- MG – Magnesium

- CR – Chromium

- ZN – Zinc

- TI – Titanium

- All compositions in percent maximum unless shown as a range or a minimum.